Today the first wall went onto the timber frame. Now I begin to see how the room will look and how it will feel. Kelley has been working hard to balance our desire to have big windows with our need for space for furniture and storage–not an easy problem to solve. But today when I came home from Puffer bellies, Bunny Vista had yet another new look.

Lewis, Aaron and Braxton framed the walls, nailed OSB to the frames, and lifted the walls up to the timber frame.

And from the inside looking out–still wonderful. I think the windows are exactly the right size–they look terrific framed by the cherry braces. The proportions are exactly right.

Topping Off the Timber Frame

Last Thursday was the start of an intense week of building at Bunny Vista. With the arrival of Jordan Finch and his crew, the number of workers at the house doubled. Lewis, Braxton, and Aaron worked alongside Jordan, Justin, and Mike to add another beautiful element to our new house. Jordan’s crew had been working on the timber frame at Jordan’s workshop in Mount Jackson for many months.

All Thursday afternoon, the crew unloaded the frame and laid it out on the house decking. They joined the wall posts to the top plate and added cherry braces while the walls lay flat on the deck. On Friday, they raised the timber frame, beginning with the west wall. They attached the floor beams for the loft, laid the loft floor joists, and raised the east wall. They maneuvered the giant cherry sling braces into place and added the four principal rafters. On those two days the men worked very hard and very long, and at the end of the day on Friday, we stood on the deck with the amazing timber frame structure surrounding us. It was very emotional for all of us.

Jordan used three woods in the timber frame. Most of the timber frame is made of cypress, which Jordan bought from a sawmill in South Carolina; it is very clear and has a lovely soft color. Kelley tells me cypress was Frank Lloyd Wright’s favorite wood. Cypress is widely used in Japan, where builders often bury it for years to deepen the color. The cherry for the braces came from a sawmill here in the Valley; the sling braces on two of the bents are about twelve feet long, eighteen inches or so wide, and six inches thick. Kelley and Jordan sawed them at the Taylor and Boody sawmill so that they retain what Kelley calls “live edges”–the edges are not sawed but follow the natural outline of the tree. They will make a stunning frame for the stone fireplace at the south end of the house. Kelley really admires the handplaning job that Mike did on the cherry, not the easiest wood to plane. The top plates run the full thirty-five foot length of the frame and are made of very dense yellow pine; Kelley and Jordan chose this wood because they were able to use one timber for the entire length of the room.

The posts flare at the top and are narrower at the bottom. Jordan specified that the lumber be milled so that the bottom of the tree (the famous butt swell) would at the top of the post to support all of the joints in that area.

Kelley recruited Nick and Erin to help him put finish on the cypress ceiling boards. Although they spent several hours on this project Sunday afternoon, they were not able to finish. There were a lot of boards.

On Monday morning, the timber frame crew returned to Bunny Vista to add the common rafters and the cypress tongue-and-groove ceiling.

After putting the rafters in place on Monday, the builders were able to apply finish to the rest of the ceiling boards, saw them to length, and nail half of them to the rafters.

At the end of the day, we had a “topping off” ceremony, which is a traditional centuries-old ceremony among timber frame builders. It marks and commemorates the completion of the timber frame; it recognizes and honors the builders. One important component of the ceremony is the nailing of the “whetting bush” , an evergreen bough, to the highest point of the frame. The origin of this tradition is obscure, but it is probably Scandinavian. Possibly, nailing the evergreen bough to the timber frame once offered appeasement to the gods for using the wood of the forest to build a structure. It may also serve to give thanks to the forest for providing wood for a new home. Kelley climbed onto the roof of the log house and nailed the whetting bush to a principal rafter of the timber frame. Jordan read a traditional German topping off toast and a house blessing which our friend Emily brought to us on Friday. Then he smashed a wine glass against the foundation of the house, and we served our first meal from what will soon be our kitchen.

Today, the rest of the ceiling boards went up. Tomorrow, Kelley and Aaron will drive to Winchester to pick up the panels that will insulate the ceiling. Thursday, the builders will add the panels to the ceiling, and we will be on our way to the next house-building adventure.

Timber Frame Raising

The timber frame arrived at Bunny Vista on Thursday. Aaron Tammi drove to Jordan Finch’s workshop in Mountain Jackson early in the morning and came back to Swoope at midday with a trailer full of house wood, shaped and ready to be made into a timber frame room. Jordan and his assistants Justin and Mike arrived at about the same time.

Jordan’s crew and Lewis’s crew spent the rest of Thursday assembling the frame and all day Friday raising it. Kelley’s brother Garry worked with them on Thursday, and our neighbor Emerson Willard worked all day Friday. Kelley and Erin and I took hundreds of photos of these two dramatic days. The photos tell the story much better than I can. I hope they give you a sense of how dramatic, exciting, and moving these two days have been.

Watching the raising of the timber frame was a once-in-a-lifetime experience. Jordan’s craftsmanship, selection and use of materials, design, planning, and execution of this project have been nothing short of brilliant. Like the stonework and the log house, the timber frame is a work of art that we will always treasure. It will be a pleasure to live in this house and a pleasure to remember the building of the house.

The Timber Frame Is on the Way

On Monday, Jordan Finch, who has been working on our timber frame room since January, will raise the frame at Bunny Vista! Picture the famous barn raising scene from the movie, “Witness.” Leave out the Amish farmers. Add a crane and a bunch of builders. You get the picture. I can hardly wait.

Before we began building Bunny Vista, I had only a nodding acquaintance with timber frame structures. I have been reading some of Kelley’s books in hopes of not embarrassing myself when I actually have a timber frame room as part of my house. (Kelley points out to everyone that I have recently read several non-fiction books–somehow he thinks that is unusual.) I have found out a little more than I once knew about this traditional method of building. I supplemented the non-fiction books that Kelley left in my path with this helpful Wikipedia article.

Timber framing was the primary building technique for residences, churches, barns, and other structures in many parts of the world for centuries. In the middle of the nineteenth century builders began to use the “stick-framing” construction we are most familiar with today, and timber frame construction almost ceased, because stick-framing was quicker and less expensive. In this country, timber framing began a renaissance in the 1960s.

In early times, timber framers hewed and shaped timbers with felling axes and broadaxes and joined them together in a system of upright (posts) and horizontal (beams) timbers with the same kind of joinery found in fine furniture. To ensure the rigidity of the frame, they used trusses and braces in various configurations. When European settlers arrived on this continent, they built timber frame houses, barns, and churches. Now, as timber framing regains popularity, many timber frame companies build houses off-site with the aid of computer numerical control machines and other modern equipment. Although Jordan uses machines in his work, every piece of wood in our timber frame will bear the mark of his own handiwork. He will use traditional joints, such as mortises and tenons. He will use wooden pegs to secure the joints, which Kelley will adjust as the wood shrinks and moves.

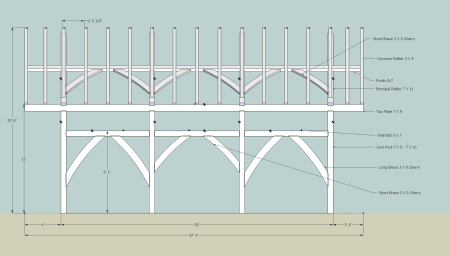

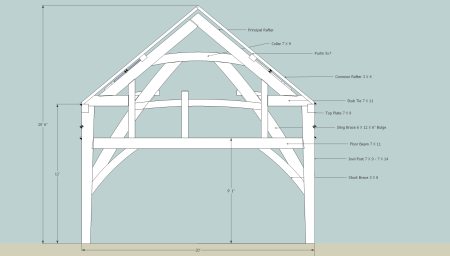

Jordan sent Kelley some labeled drawings of the timber frame room. Our room will have four bents and three bays, as seen in the drawing below. Now, if you don’t know what bents and bays are, I will explain as Kelley explained to me: if you imagine the side view of the room as the side view of a sliced loaf of bread, each of the four slices coming up from the bottom of the loaf represents the side view of a post rising from the floor. Between each post is an open area called a bay. At the left will be the fireplace. At the right will be stairs leading up to a loft and down to the basement.

The photo below is a labeled view of one of the four bents. Imagining the loaf of bread again, think of the bent as a slice of that bread. The main parts of the bent are the posts rising from the floor, the beam, and the braces which form triangles between posts and the beam. (These braces keep the bent rigid. Triangles are rigid forms, but squares are not. Structures built without triangular bracing are going to fall right down in a strong wind.) There are also rafters. The drawing below combines elements from a couple of the bents. The sling braces will be only on the two bents near the fireplace. The floor beam will be on the two posts nearest the log house and will support the loft floor. The railing for the loft is also pictured here.

Many of the terms Kelley, Jordan, Lewis, and our architect Peter use with such authority and gusto are completely foreign to me. I found this useful glossary of timber frame terms on the beautiful Dreaming Creek Architectural Timbering Website. I sneak peeks at it rather often.